In 1911, Dutch physicist Heike Kamerlingh Onnes plunged a mercury wire into liquid helium and noticed that the wire’s electrical resistance vanished. The wire had become a “superconductor.”

The extremely low temperatures and high pressures needed to induce superconductivity limited its practical value for decades. But the 1986 discovery of high-temperature superconductivity paved the way for broader applications.

“High temperature” isn’t room temperature. It refers to materials that superconduct above −195.79 °C, the boiling point of liquid nitrogen. Lately, new materials and configurations are boosting the temperatures at which these superconductors can operate, making them easier to work with. This newest generation is especially prized for the high magnetic fields the materials can generate.

“Over the past 15 years, the emphasis has moved toward using [these materials] less as high-temperature superconductors and more as high-field superconductors,” says Venkat Selvamanickam, who directs the Applied Research Hub of the Texas Center for Superconductivity at the University of Houston.

Those high magnetic fields may one day enable nuclear fusion energy, which I wrote about recently [see “This Fusion Reactor Is Held Together With Tape”]. But the materials could show up sooner in a wide array of practical applications, including wind power, energy storage, and nuclear magnetic resonance machines. Here are five emerging uses for HTS that could transform everyday life—if engineers can work out the kinks.

Energy Storage

Unlike conventional batteries, which use chemicals to store energy, superconducting magnetic energy storage (SMES) uses a magnetic field created by the flow of direct current in a coil of superconducting material. Once the coil is charged, the energy can be stored nearly indefinitely with little to no decay, provided that the cooling is maintained. The stored energy increases as the square of the magnetic field—that is, with each doubling of the field strength, the system can store four times as much energy. These systems can release bursts of power almost instantaneously, so they could play a crucial role in utility grids, particle accelerators, and industrial systems that support sensitive, high-speed processes.

Hybrid storage systems that combine the superfast discharge of SMES with the higher energy densities of batteries are a promising area of research. As with the other HTS applications, cryogenic cooling boosts costs, as does the need for strong mechanical structures to withstand the Lorentz forces generated by and on the magnet coils.

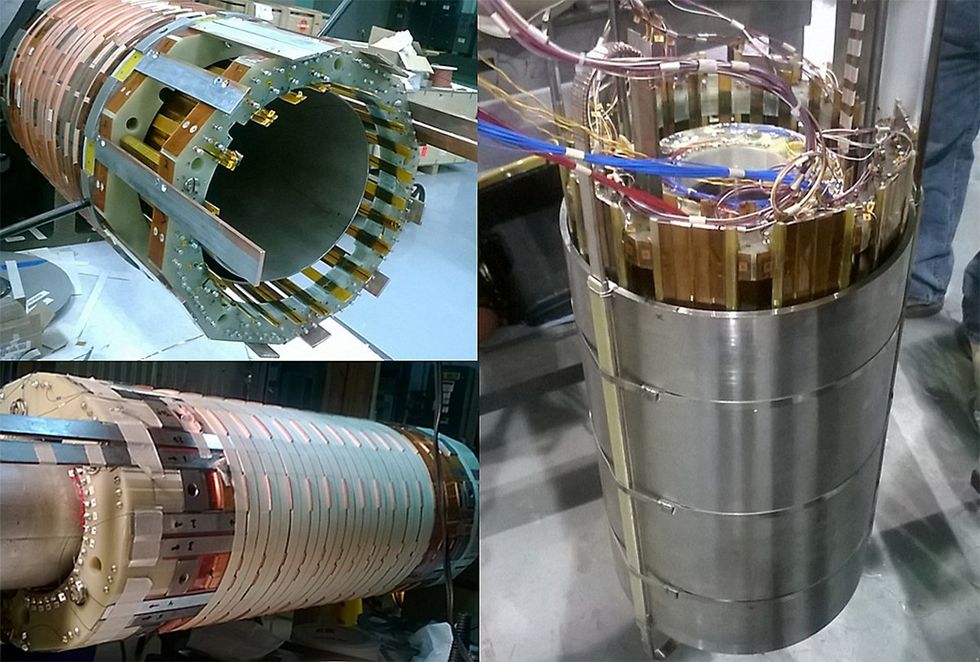

This energy storage device uses a magnetic field created by the flow of direct current in a coil of superconducting material. Brookhaven National Laboratory

This energy storage device uses a magnetic field created by the flow of direct current in a coil of superconducting material. Brookhaven National Laboratory

PROOF OF CONCEPT: A research team led by Brookhaven National Laboratory and ABB built a magnetic energy storage system using HTS that achieved a 12.5-Tesla magnetic field in 2014. Since then, research has lagged due to the high cost of the materials.

Induction Heaters

The industrial processes that heat aluminum ingots, forge non-ferrous metals, and smelt high-end alloys are extremely energy intensive. HTS induction heaters promise to halve energy use, along with greenhouse gas emissions.

One HTS induction heater now moving to commercialization rotates a metal ingot within a magnetic field to generate eddy currents within the metal. With conventional induction heating, these currents are slow to penetrate the ingot. The HTS system’s strong magnetic field boosts penetration for faster and more uniform heating.

PROJECT TO WATCH: Earlier this year, the Chinese company Lianovation installed the world’s first megawatt-level HTS induction heater at an industrial facility in northeastern China. Conventional methods required at least nine hours to heat a 500-kilogram aluminum ingot from 20 °C to 403 °C. Using the new HTS heater, the process takes about 10 minutes.

Aviation

The biggest challenge of using electric propulsion in aviation is the power-to-weight ratio: Conventional electrical systems can’t produce sufficient thrust without weighing down the aircraft. HTS materials offer high power density and high efficiency in a compact and lightweight package. They could also lighten other electrical systems, such as flight controls, communications, and power electronics. For safe flight, future HTS aircraft will need to build in redundant systems to counter the possibility of quenching—the loss of magnetism when an HTS material’s temperature is raised.

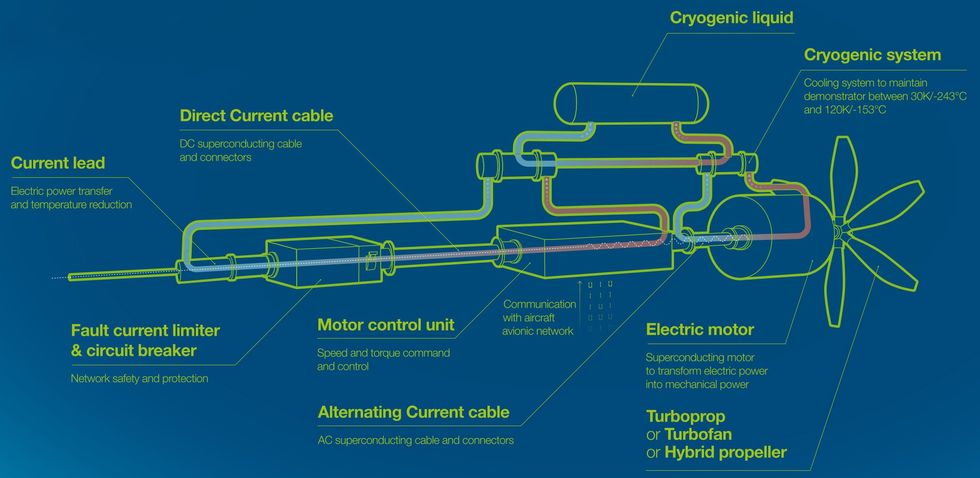

Airbus is working on a superconducting electric motor that uses liquid hydrogen for cooling as well as fuel.Airbus

Airbus is working on a superconducting electric motor that uses liquid hydrogen for cooling as well as fuel.Airbus

PROJECT TO WATCH: Airbus’s ASCEND project aims to demonstrate a powertrain incorporating superconducting motors and a cryogenic cooling system. Calculations suggest that the system could be one-third to one-half the weight of conventional electric aircraft propulsion, while achieving a 97-percent powertrain efficiency. The concept is based on using liquid hydrogen as both a refrigerant and a fuel. Airbus hasn’t said how the hydrogen will be produced, but the company does participate in industry research on renewable sources of hydrogen.

Superconducting Wind Turbines

Over the last few decades, wind turbine capacities have soared, from just 50 kilowatts in 1985 to 15 megawatts today, thanks to bigger turbines with bigger magnets that can generate stronger electromagnetic fields. But the quest for efficiency is running into headwinds, as more power generally equates to more weight. Also, the rare-earth elements used in permanent-magnet generators, such as neodymium and dysprosium, are in short supply.

HTS technology provides a promising pathway to a new generation of highly efficient and lower cost turbines. Replacing permanent magnets with superconducting windings can create a much stronger magnetic field, cutting the weight of generators in half and minimizing the need for rare earths.

EcoSwing’s compact generator [blue] for wind turbines uses kilometers of a ribbon-like HTS that has 100 times the power density of copper.Jan Meier/Fraunhofer IWES

EcoSwing’s compact generator [blue] for wind turbines uses kilometers of a ribbon-like HTS that has 100 times the power density of copper.Jan Meier/Fraunhofer IWES

PROOF OF CONCEPT: The European Union-funded EcoSwing project, completed in 2019, installed a 3.6-megawatt wind turbine on the Danish North Sea coast that contains 20 kilometers of HTS wire made of gadolinium, barium, and copper oxide. The generator weighs 40 percent less than conventional units, and the nacelle—the housing for the generator and other machinery—is 25 percent smaller. HTS winding material is still expensive, but costs should fall as the technology matures.

Medical Diagnostics and Research

Magnetic resonance imaging is a popular diagnostic tool, thanks to its superior soft-tissue imaging and lack of ionizing radiation. MRIs are also extraordinarily expensive—as anyone who has received an MRI bill knows. To cool the superconducting magnets to −269 °C, today’s machines typically use liquid helium, an increasingly scarce commodity.

Once costs come down, higher-temperature superconducting coils could offer a sustainable alternative to helium-cooled MRI magnets, reducing the size, weight, and energy consumption of the machines. Already, HTS technology is being incorporated into nuclear magnetic resonance machines used to study materials at the molecular level. Because of their higher magnetic fields, HTS technology can dramatically raise signal-to-noise ratios, resulting in more detailed and accurate imaging.

PROJECT TO WATCH: Scientific instrument maker Bruker’s newest spectrometers sandwich an inner coil of HTS between an outer coil of low-temperature superconductors, achieving magnetic flux densities of 28.2 Tesla—nearly 600,000 times as strong as the Earth’s magnetic field.

Reference: https://ift.tt/Vlp8QXW

No comments:

Post a Comment