The conventional way of adding a robot to your business is to pay someone else a lot of money to do it for you. While robots are a heck of a lot easier to program than they once were, they’re still kind of scary for nonroboticists, and efforts to make robotics more accessible to folks with software experience but not hardware experience haven’t really gotten anywhere. Obviously, there are all kinds of opportunities for robots (even simple robots) across all kinds of industries, but the barrier to entry is very high when the only way to realistically access those opportunities is to go through a system integrator. This may make sense for big companies, but for smaller businesses, it could be well out of reach.

Today, Intrinsic (the Alphabet company that acquired Open Robotics a little while back) is announcing its first product. Flowstate, in the word of Intrinsic’s press release, is “an intuitive, web-based developer environment to build robotic applications from concept to deployment.” We spoke with Intrinsic CEO Wendy Tan White along with Brian Gerkey, who directs the Open Robotics team at Intrinsic, to learn more about how Intrinsic hopes to use Flowstate to change industrial robotics development.

“Our mission is, in short, to democratize access to robotics. We’re making the ability to program intelligent robotic solutions as simple as standing up a website or mobile application.” —Wendy Tan White, Intrinsic CEO

To be honest, we’ve heard this sort of thing many times before: How robots will be easy now, and how you won’t need to be a roboticist (or hire a dedicated roboticist) to get them to do useful stuff. Robots have gotten somewhat easier over the years (even as they’ve gotten both more capable and more complicated), but this dream of every software developer also being able to develop robotics applications for robots hasn’t ever really materialized.

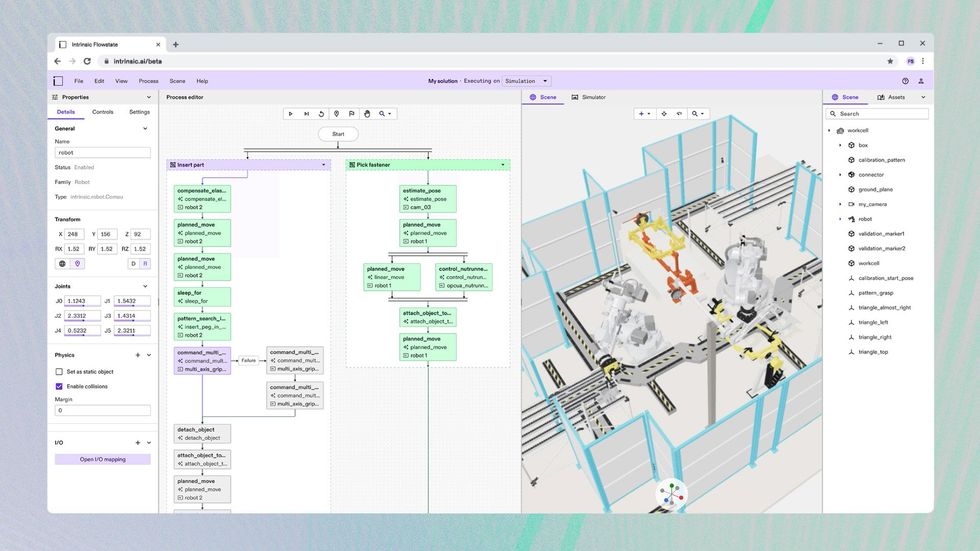

Intrinsic’s Flowstate developer environment is intended to take diverse robotic hardware and make it all programmable through one single accessible software system. If that sounds kind of like what Open Robotics’ Robot Operating System (ROS) does, well, that shouldn’t be much of a surprise. Here are some highlights from the press release:

- Includes a graphical process builder that removes the need for extensive programming experience

- Behavior trees make it easy to orchestrate complex process flows, authored through a flowchart-inspired graphical representation

- Lay out a workcell and design a process in the same virtual environment, in the cloud or on-premise

- Simulate and validate solutions in real time (using Gazebo) without touching a single piece of hardware

- Encode domain knowledge in custom skills that can be used and reused, with basic skills like pose estimation, manipulation, force-based insertion, and path planning available at launch

- Fully configured development environment provides clear APIs to contribute new skills to the platform

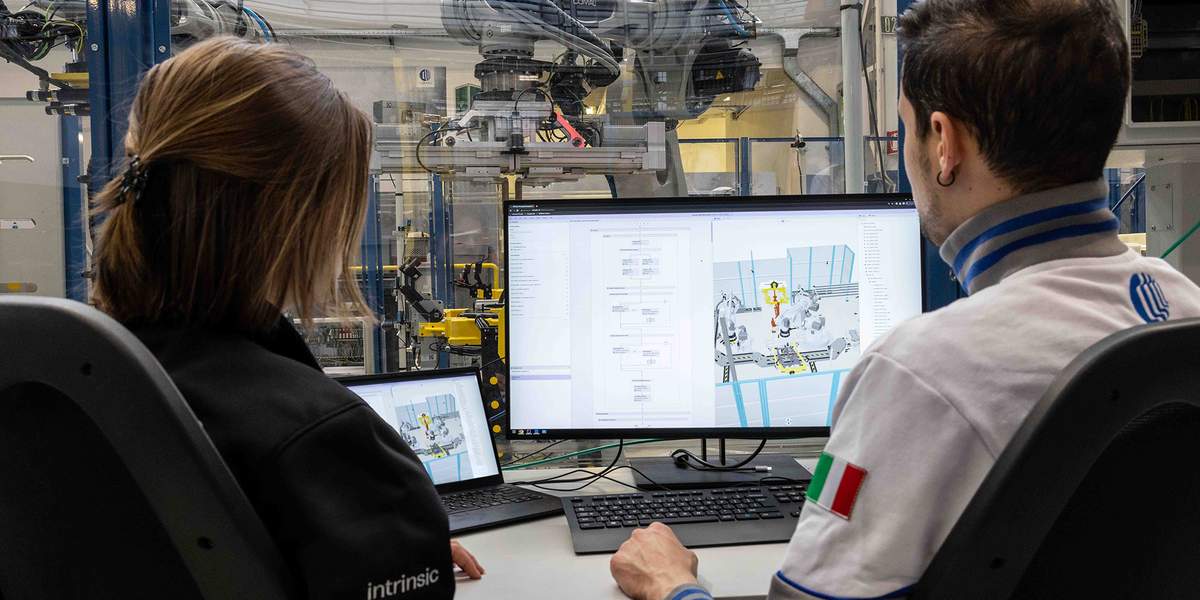

Intrinsic’s Flowstate development environment.Intrinsic

Intrinsic’s Flowstate development environment.Intrinsic

Intrinisic’s industry partner on this for the last several years is Comau, an Italian automation company that you may not have heard of but apparently built the first robotic assembly line in 1979—if a Wikipedia article with a bad citation is to be believed. Anyway, Comau currently does a lot of robotic automation in the automotive industry, so it has been able to help Intrinsic make sure that Flowstate is real-world useful. The company will be showing it off at Automatica, if you happen to find yourself in Munich at the end of June.

For some additional background and context and details and all that good stuff, we had a chat with Wendy Tan White and Brian Gerkey.

Intrinsic is certainly not the first company to work toward making it easier to program and deploy robots. How is your approach different, and why is it going to work?

Wendy Tan White: One of the things that’s really important to make robotics accessible is agnosticism. In robotics, much of the hardware is proprietary and not very interoperable. We’re looking at bridging that. And then there’s also who can actually develop the applications. At the moment, it still takes even an integrator or a developer multiple types of software to actually build an application, or they have to build it from scratch themselves, and if you want to add anything more sophisticated like force feedback or vision, you need a specialist. What we’re looking to do with our product is to encapsulate all of that, so that whether you’re a process engineer or a software developer, you can launch an application much easier and much faster without repeatedly rebuilding the plumbing every time.

Not having to rebuild the plumbing with every new application has been one of the promises of ROS, though. So how is your tool actually solving this problem?

Brian Gerkey: ROS handles the agnosticism quite well—it gives you a lot of the developer tools that you need. What it doesn’t give you is an application building experience that’s approachable, unless you’re already a software engineer. What I said in the early days of ROS was that we want to make it possible for every software developer to build robot applications. And I think we got pretty close. Now, we’re going a step further and saying, actually, you don’t even need to be a programmer, because we can give you this low/no code type of experience where you can still access all of that underlying functionality and build a fairly complex robot application.

And then also, as you know with ROS, it gives you the toolbox, but deploying an application is basically on you: How are you actually going to roll it out? How do you tie it into a cloud system? How do you have simulation be in the loop as part of the iterative development experience, and then the continuous integration and testing experience? So, there’s a lot of room between ROS as it exists today and a fully integrated product that ties all that together.

White: Bluntly, this is going to be our first product release. So you’ll get a sense of all of that from the beginning, but my guess is that it’s not going to complete everybody’s needs through the whole pipeline straight away, although it will satisfy a subset of folks. And from there you’ll see what we’re going to add in.

Brian, is this getting closer to what your vision for making ROS accessible has always been?

Gerkey: There was always this sense that we never had the opportunity to take the platform as it is, as a set of tools, and really finish it. Like, turn up the level of professionalism and polish and really integrate it seamlessly into a product, which is frankly what you would expect out of most modern open source projects. As an independent entity, it was difficult to find the resources necessary to invest in that kind of effort. With Intrinsic, we have the opportunity now to do both things—we have the opportunity to invest more in the underlying core, which we’re doing, and we also get to go beyond that and tie it all together into a unified product vision. I want to be clear, though, that the product that we’re announcing next week will not be that, because in large part it’s a product that’s been built independently over the last several years and has a different heritage. We’ll incrementally bring in more components from the ROS ecosystem into the Intrinsic stack, and there will be things that are developed on the Intrinsic side that we will push back into the ROS community as open source.

White: The intention is very much to converge the Intrinsic platform and ROS over time. And as Brian said, I really hope that a lot of what we develop together will go back into open source.

“We believe in the need for a holistic platform. One that makes it more seamless to use different types of hardware and software together…a platform that will benefit everyone in the robotics and automation industry.” —Wendy Tan White, Intrinsic CEO

What should experienced ROS users be most excited about?

Gerkey: We’re going to provide ROS users an on-ramp to bring their existing ROS-based systems into the Intrinsic systems. What they’ll then be able to do that they can’t do today is, for example, using a Web-native graphical tool, design the process flow for a real-world industrial application. They’ll be able to integrate that with a cloud-hosted simulation that lets them iteratively test what they’re building as they develop it to confirm that it works. They’ll have a way to then run that application on real hardware, using the same interface. They’ll have a pipeline to then deploy that to an edge device. ROS lets you do a lot of that stuff today, but it doesn’t include the unified development experience nor the deployment end of things.

How are you going to convince other companies to work with you on this product?

White: At the beginning, when we spoke to OEMs [original equipment manufacturers] and integrators, they were like, “Hang on a minute, we like our business model, why would we open up our software to you?” But actually, they’re all finding that they can’t meet demand. They need better, more efficient ways to build solutions for their customers. There has been a shift, and now they want things like this.

Gerkey: I’d like to give credit as well to the ROS Industrial Consortium that has spent the last 10 years getting robot OEMs and integrators and customers to work together on common problems. Initially, people thought that there was no way that the robot manufacturers were going to participate: They have their own vertically integrated software solutions, and that’s what they want their customers to use. But in fact, there’s additional value from interoperability with other software ecosystems, and you can sell more robots if they’re more flexible and more usable.

With much of the functionality of your platform being dependent on skills, what is the incentive for people to share new skills that they develop?

White: We do intend to ultimately become a distribution platform. So, what we would expect is if people add skills to the platform, they will get compensated. We’re really creating a demand and supply marketplace, but we’re not starting there—our first product will be the solution builder itself, to prove that the value is there.

Gerkey: We’ve demonstrated that there’s huge potential to get people to share what they’re doing. Everyone has different motivations—could be karma, could be altruism, but sharing the engineering burden is the more rational reason to participate in the open source community. And then on top of all those potential motivations, here we’ve got the opportunity to set up this distribution channel where they can get paid as well.

And what’s the incentive for Intrinsic? How is this a business for you?

White: Initially there will be a developer license. What we’re looking for longer term as applications are built is a fee per application used, and ultimately per robot deployed. We have partners already who are willing to pay for this, so that’s how we know it’s a good place to start.

As we’ve pointed out, this is not the first attempt at making industrial robots easy to program for nonroboticists, nor is it the first attempt at launching a sort of robot app store. Having said that, if anyone can actually make this work, it sure seems like it would be this current combination of Intrinsic and Open Robotics.

If Flowstate seems interesting to you and you want to give it a try, you can apply to join the private beta here.

Reference: https://ift.tt/2JZnYDK

No comments:

Post a Comment