There’s a handful of robotics companies currently working on what could be called general-purpose humanoid robots. That is, human-size, human-shaped robots with legs for mobility and arms for manipulation that can (or, may one day be able to) perform useful tasks in environments designed primarily for humans. The value proposition is obvious—drop-in replacement of humans for dull, dirty, or dangerous tasks. This sounds a little ominous, but the fact is that people don’t want to be doing the jobs that these robots are intended to do in the short term, and there just aren’t enough people to do these jobs as it is.

We tend to look at claims of commercializable general-purpose humanoid robots with some skepticism, because humanoids are really, really hard. They’re still really hard in a research context, which is usually where things have to get easier before anyone starts thinking about commercialization. There are certainly companies out there doing some amazing work toward practical legged systems, but at this point, “practical” is more about not falling over than it is about performance or cost effectiveness. The overall approach toward solving humanoids in this way tends to be to build something complex and expensive that does what you want, with the goal of cost reduction over time to get it to a point where it’s affordable enough to be a practical solution to a real problem.

Apptronik, based in Austin, Texas, is the latest company to attempt to figure out how to make a practical general-purpose robot. Its approach is to focus on things like cost and reliability from the start, developing (for example) its own actuators from scratch in a way that it can be sure will be cost effective and supply-chain friendly. Apptronik’s goal is to develop a platform that costs well under US $100,000 of which it hopes to be able to deliver a million by 2030, although the plan is to demonstrate a prototype early this year. Based on what we’ve seen of commercial humanoid robots recently, this seems like a huge challenge. And in part two of this story (to be posted tomorrow

), we will be talking in depth to Apptronik’s cofounders to learn more about how they’re going to make general-purpose humanoids happen.

First, though, some company history. Apptronik spun out from the Human Centered Robotics Lab at the University of Texas at Austin in 2016, but the company traces its robotics history back a little farther, to 2015’s DARPA Robotics Challenge. Apptronik’s CTO and cofounder, Nick Paine, was on the NASA-JSC Valkyrie DRC team, and Apptronik’s first contract was to work on next-gen actuation and controls for NASA. Since then, the company has been working on robotics projects for a variety of large companies. In particular, Apptronik developed Astra, a humanoid upper body for dexterous bimanual manipulation that’s currently being tested for supply-chain use.

But Apptronik has by no means abandoned its NASA roots. In 2019, NASA had plans for what was essentially going to be a Valkyrie 2, which was to be a ground-up redesign of the Valkyrie platform. As with many of the coolest NASA projects, the potential new humanoid didn’t survive budget prioritization for very long, but even at the time it wasn’t clear to us why NASA wanted to build its own humanoid rather than asking someone else to build one for it considering how much progress we’ve seen with humanoid robots over the last decade. Ultimately, NASA decided to move forward with more of a partnership model, which is where Apptronik fits in—a partnership between Apptronik and NASA will help accelerate commercialization of Apollo.

“We recognize that Apptronik is building a production robot that’s designed for terrestrial use,” says NASA’s Shaun Azimi, who leads the Dexterous Robotics Team at NASA’s Johnson Space Center. “From NASA’s perspective, what we’re aiming to do with this partnership is to encourage the development of technology and talent that will sustain us through the Artemis program and looking forward to Mars.”

Apptronik is positioning Apollo as a high-performance, easy-to-use, and versatile system. It is imagining an “iPhone of robots.”

“Apollo is the robot that we always wanted to build,” says Jeff Cardenas, Apptronik cofounder and CEO. This new humanoid is the culmination of an astonishing amount of R&D, all the way down to the actuator level. “As a company, we’ve built more than 30 unique electric actuators,” Cardenas explains. “You name it, we’ve tried it. Liquid cooling, cable driven, series elastic, parallel elastic, quasi-direct drive…. And we’ve now honed our approach and are applying it to commercial humanoids.”

Apptronik’s emphasis on commercialization gives it a much different perspective on robotics development than you get when focusing on pure research the way that NASA does. To build a commercial product rather than a handful of totally cool but extremely complex bespoke humanoids, you need to consider things like minimizing part count, maximizing maintainability and robustness, and keeping the overall cost manageable. “Our starting point was figuring out what the minimum viable humanoid robot looked like,” explains Apptronik CTO Nick Paine. “Iteration is then necessary to add complexity as needed to solve particular problems.”

This robot is called Astra. It’s only an upper body, and it’s Apptronik’s first product, but (not having any legs) it’s designed for manipulation rather than dynamic locomotion. Astra is force controlled, with series-elastic torque-controlled actuators, giving it the compliance necessary to work in dynamic environments (and particularly around humans). “Astra is pretty unique,” says Paine. “What we were trying to do with the system is to approach and achieve human-level capability in terms of manipulation workspace and payload. This robot taught us a lot about manipulation and actually doing useful work in the world, so that’s why it’s where we wanted to start.”

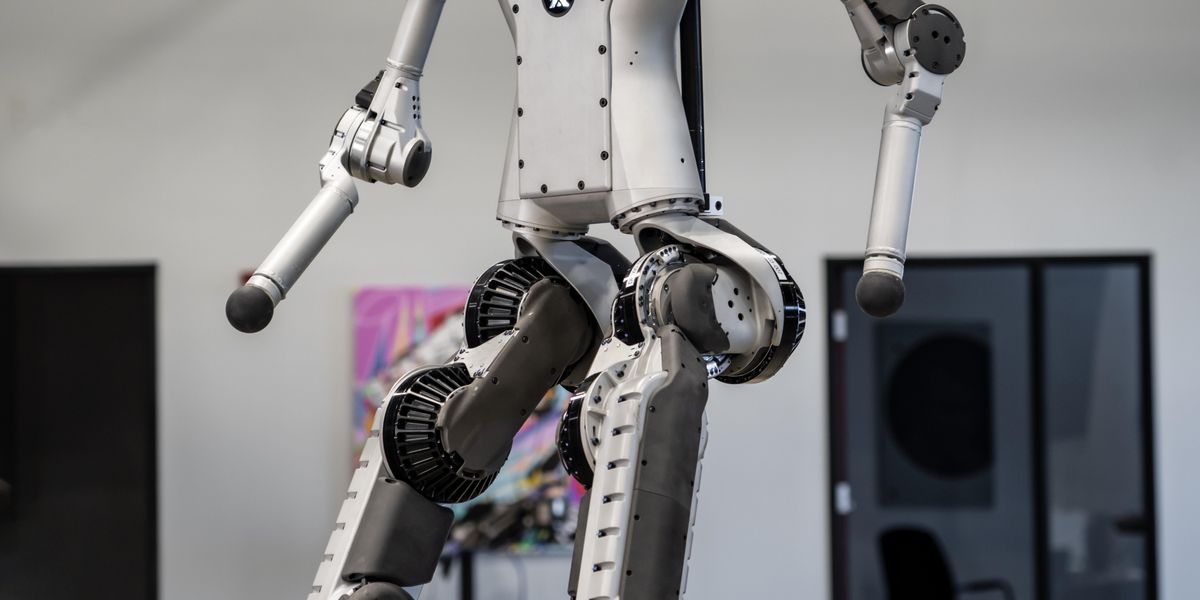

While Astra is currently out in the world doing pilot projects with clients (mostly in the logistics space), internally Apptronik has moved on to robots with legs. The following video, which Apptronik is sharing publicly for the first time, shows a robot that the company is calling its Quick Development Humanoid, or QDH:

QDH builds on Astra by adding legs, along with a few extra degrees of freedom in the upper body to help with mobility and balance while simplifying the upper body for more basic manipulation capability. It uses only three different types of actuators, and everything (from structure to actuators to electronics to software) has been designed and built by Apptronik. “With QDH, we’re approaching minimum viable product from a usefulness standpoint,” says Paine, “and this is really what’s driving our development, both in software and hardware.”

“What people have done in humanoid robotics is to basically take the same sort of architectures that have been used in industrial robotics and apply those to building what is in essence a multi-degree-of-freedom industrial robot,” adds Cardenas. “We’re thinking of new ways to build these systems, leveraging mass manufacturing techniques to allow us to develop a high-degree-of-freedom robot that’s as affordable as many industrial robots that are out there today.”

Cardenas explains that a major driver for the cost of humanoid robots is the number of different parts, the precision machining of some specific parts, and the resulting time and effort it then takes to put these robots together. As an internal-controls test bed, QDH has helped Apptronik to explore how it can switch to less complex parts and lower the total part count. The plan for Apollo is to not use any high-precision or proprietary components at all, which mitigates many supply-chain issues and will help Apptronik reach its target price point for the robot.

Apollo will be a completely new robot, based around the lessons Apptronik has learned from QDH. It’ll be average human size: about 1.75 meters tall, weighing around 75 kilograms, with the ability to lift 25 kg. It’s designed to operate untethered, either indoors or outdoors. Broadly, Apptronik is positioning Apollo as a high-performance, easy-to-use, and versatile robot that can do a bunch of different things. It is imagining an “iPhone of robots,” where apps can be created for the robot to perform specific tasks. To extend the iPhone metaphor, Apptronik itself will make sure that Apollo can do all of the basics (such as locomotion and manipulation) so that it has fundamental value, but the company sees versatility as the way to get to large-scale deployments and the cost savings that come with them.

“I see the Apollo robot as a spiritual successor to Valkyrie. It’s not Valkyrie 2—Apollo is its own platform, but we’re working with Apptronik to adapt it as much as we can to space use cases.”

—Shaun Azimi, NASA Johnson Space Center

The challenge with this app approach is that there’s a critical mass that’s required to get it to work—after all, the primary motivation to develop an iPhone app is that there are a bajillion iPhones out there already. Apptronik is hoping that there are enough basic manipulation tasks in the supply-chain space that Apollo can leverage to scale to that critical-mass point. “This is a huge opportunity where the tasks that you need a robot to do are pretty straightforward,” Cardenas tells us. “Picking single items, moving things with two hands, and other manipulation tasks where industrial automation only gets you to a certain point. These companies have a huge labor challenge—they’re missing labor across every part of their business.”

While Apptronik’s goal is for Apollo to be autonomous, in the short to medium term, its approach will be hybrid autonomy, with a human overseeing first a few and eventually a lot of Apollos with the ability to step in and provide direct guidance through teleoperation when necessary. “That’s really where there’s a lot of business opportunity,” says Paine. Cardenas agrees. “I came into this thinking that we’d need to make Rosie the robot before we could have a successful commercial product. But I think the bar is much lower than that. There are fairly simple tasks that we can enter the market with, and then as we mature our controls and software, we can graduate to more complicated tasks.”

Apptronik is still keeping details about Apollo’s design under wraps, for now. We were shown renderings of the robot, but Apptronik is understandably hesitant to make those public, since the design of the robot may change. It does have a firm date for unveiling Apollo for the first time: SXSW, which takes place in Austin in March.

Reference: https://ift.tt/ObCaLce

No comments:

Post a Comment