It may at times seem like there are as many humanoid robotics companies out there as the industry could possibly sustain, but the potential for useful and reliable and affordable humanoids is so huge that there’s plenty of room for any company that can actually get them to work. Joining the dozen or so companies already on this quest is Persona AI, founded last month by Nic Radford and Jerry Pratt, two people who know better than just about anyone what it takes to make a successful robotics company, although they also know enough to be wary of getting into commercial humanoids.

Persona AI may not be the first humanoid robotics startup, but its founders have some serious experience in the space:

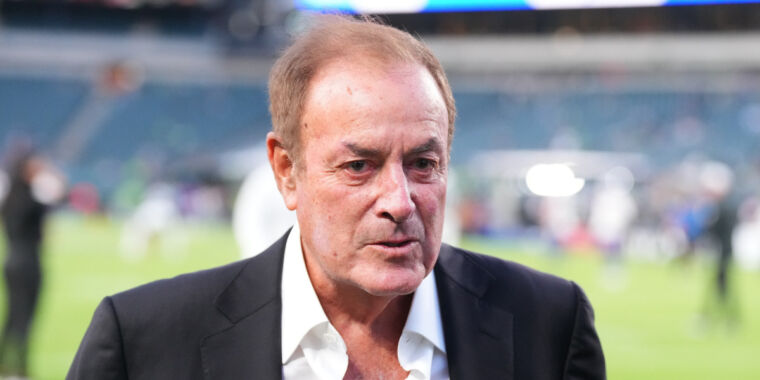

Nic Radford lead the team that developed NASA’s Valkyrie humanoid robot, before founding Houston Mechatronics (now Nauticus Robotics), which introduced a transforming underwater robot in 2019. He also founded Jacobi Motors, which is commercializing variable flux electric motors.

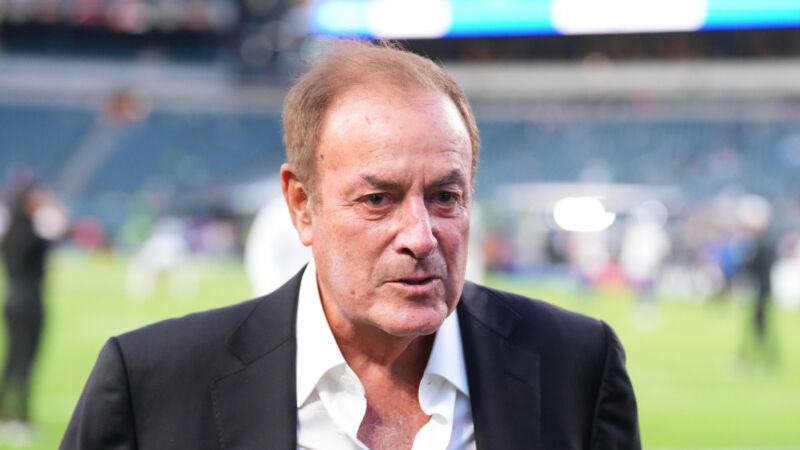

Jerry Pratt worked on walking robots for 20 years at the Institute for Human and Machine Cognition (IHMC) in Pensacola, Florida. He co-founded Boardwalk Robotics in 2017, and has spent the last two years as CTO of multi-billion-dollar humanoid startup Figure.

“It took me a long time to warm up to this idea,” Nic Radford tells us. “After I left Nauticus in January, I didn’t want anything to do with humanoids, especially underwater humanoids, and I didn’t even want to hear the word ‘robot.’ But things are changing so quickly, and I got excited and called Jerry and I’m like, this is actually very possible.” Jerry Pratt, who recently left Figure due primarily to the two-body problem, seems to be coming from a similar place: “There’s a lot of bashing your head against the wall in robotics, and persistence is so important. Nic and I have both gone through pessimism phases with our robots over the years. We’re a bit more optimistic about the commercial aspects now, but we want to be pragmatic and realistic about things too.”

Behind all of the recent humanoid hype lies the very, very difficult problem of making a highly technical piece of hardware and software compete effectively with humans in the labor market. But that’s also a very, very big opportunity—big enough that Persona doesn’t have to be the first company in this space, or the best funded, or the highest profile. They simply have to succeed, but of course sustainable commercial success with any robot (and bipedal robots in particular) is anything but simple. Step one will be building a founding team across two locations: Houston and Pensacola, Fla. But Radford says that the response so far to just a couple of LinkedIn posts about Persona has been “tremendous.” And with a substantial seed investment in the works, Persona will have more than just a vision to attract top talent.

For more details about Persona, we spoke with Persona AI co-founders Nic Radford and Jerry Pratt.

Why start this company, why now, and why you?

Nic Radford

Nic Radford

Nic Radford: The idea for this started a long time ago. Jerry and I have been working together off and on for quite a while, being in this field and sharing a love for what the humanoid potential is while at the same time being frustrated by where humanoids are at. As far back as probably 2008, we were thinking about starting a humanoids company, but for one reason or another the viability just wasn’t there. We were both recently searching for our next venture and we couldn’t imagine sitting this out completely, so we’re finally going to explore it, although we know better than anyone that robots are really hard. They’re not that hard to build; but they’re hard to make useful and make money with, and the challenge for us is whether we can build a viable business with Persona: can we build a business that uses robots and makes money? That’s our singular focus. We’re pretty sure that this is likely the best time in history to execute on that potential.

Jerry Pratt: I’ve been interested in commercializing humanoids for quite a while—thinking about it, and giving it a go here and there, but until recently it has always been the wrong time from both a commercial point of view and a technological readiness point of view. You can think back to the DARPA Robotics Challenge days when we had to wait about 20 seconds to get a good lidar scan and process it, which made it really challenging to do things autonomously. But we’ve gotten much, much better at perception, and now, we can get a whole perception pipeline to run at the framerate of our sensors. That’s probably the main enabling technology that’s happened over the last 10 years.

From the commercial point of view, now that we’re showing that this stuff’s feasible, there’s been a lot more pull from the industry side. It’s like we’re at the next stage of the Industrial Revolution, where the harder problems that weren’t roboticized from the 60s until now can now be. And so, there’s really good opportunities in a lot of different use cases.

A bunch of companies have started within the last few years, and several were even earlier than that. Are you concerned that you’re too late?

Radford: The concern is that we’re still too early! There might only be one Figure out there that raises a billion dollars, but I don’t think that’s going to be the case. There’s going to be multiple winners here, and if the market is as large as people claim it is, you could see quite a diversification of classes of commercial humanoid robots.

Jerry Pratt

Jerry Pratt

Pratt: We definitely have some catching up to do but we should be able to do that pretty quickly, and I’d say most people really aren’t that far from the starting line at this point. There’s still a lot to do, but all the technology is here now—we know what it takes to put together a really good team and to build robots. We’re also going to do what we can to increase speed, like by starting with a surrogate robot from someone else to get the autonomy team going while building our own robot in parallel.

Radford: I also believe that our capital structure is a big deal. We’re taking an anti-stealth approach, and we want to bring everyone along with us as our company grows and give out a significant chunk of the company to early joiners. It was an anxiety of ours that we would be perceived as a me-too and that nobody was going to care, but it’s been the exact opposite with a compelling response from both investors and early potential team members.

So your approach here is not to look at all of these other humanoid robotics companies and try and do something they’re not, but instead to pursue similar goals in a similar way in a market where there’s room for all?

Pratt: All robotics companies, and AI companies in general, are standing on the shoulders of giants. These are the thousands of robotics and AI researchers that have been collectively bashing their heads against the myriad problems for decades—some of the first humanoids were walking at Waseda University in the late 1960s. While there are some secret sauces that we might bring to the table, it is really the combined efforts of the research community that now enables commercialization.

So if you’re at a point where you need something new to be invented in order to get to applications, then you’re in trouble, because with invention you never know how long it’s going to take. What is available today and now, the technology that’s been developed by various communities over the last 50+ years—we all have what we need for the first three applications that are widely mentioned: warehousing, manufacturing, and logistics. The big question is, what’s the fourth application? And the fifth and the sixth? And if you can start detecting those and planning for them, you can get a leg up on everybody else.

The difficulty is in the execution and integration. It’s a ten thousand—no, that’s probably too small—it’s a hundred thousand piece puzzle where you gotta get each piece right, and occasionally you lose some pieces on the floor that you just can’t find. So you need a broad team that has expertise in like 30 different disciplines to try to solve the challenge of an end-to-end labor solution with humanoid robots.

Radford: The idea is like one percent of starting a company. The rest of it, and why companies fail, is in the execution. Things like, not understanding the market and the product-market fit, or not understanding how to run the company, the dimensions of the actual business. I believe we’re different because with our backgrounds and our experience we bring a very strong view on execution, and that is our focus on day one. There’s enough interest in the VC community that we can fund this company with a singular focus on commercializing humanoids for a couple different verticals.

But listen, we got some novel ideas in actuation and other tricks up our sleeve that might be very compelling for this, but we don’t want to emphasize that aspect. I don’t think Persona’s ultimate success comes just from the tech component. I think it comes mostly from ‘do we understand the customer, the market needs, the business model, and can we avoid the mistakes of the past?’

How is that going to change things about the way that you run Persona?

Radford: I started a company [Houston Mechatronics] with a bunch of research engineers. They don’t make the best product managers. More broadly, if you’re staffing all your disciplines with roboticists and engineers, you’ll learn that it may not be the most efficient way to bring something to market. Yes, we need those skills. They are essential. But there’s so many other aspects of a business that get overlooked when you’re fundamentally a research lab trying to commercialize a robot. I’ve been there, I’ve done that, and I’m not interested in making that mistake again.

Pratt: It’s important to get a really good product team that’s working with a customer from day one to have customer needs drive all the engineering. The other approach is ‘build it and they will come’ but then maybe you don’t build the right thing. Of course, we want to build multi-purpose robots, and we’re steering clear of saying ‘general purpose’ at this point. We don’t want to overfit to any one application, but if we can get to a dozen use cases, two or three per customer site, then we’ve got something.

There still seems to be a couple of unsolved technical challenges with humanoids, including hands, batteries, and safety. How will Persona tackle those things?

Pratt: Hands are such a hard thing—getting a hand that has the required degrees of freedom and is robust enough that if you accidentally hit it against your table, you’re not just going to break all your fingers. But we’ve seen robotic hand companies popping up now that are showing videos of hitting their hands with a hammer, so I’m hopeful.

Getting one to two hours of battery life is relatively achievable. Pushing up towards five hours is super hard. But batteries can now be charged in 20 minutes or so, as long as you’re going from 20 percent to 80 percent. So we’re going to need a cadence where robots are swapping in and out and charging as they go. And batteries will keep getting better.

Radford: We do have a focus on safety. It was paramount at NASA, and when we were working on Robonaut, it led to a lot of morphological considerations with padding. In fact, the first concepts and images we have of our robot illustrate extensive padding, but we have to do that carefully, because at the end of the day it’s mass and it’s inertia.

What does the near future look like for you?

Pratt: Building the team is really important—getting those first 10 to 20 people over the next few months. Then we’ll want to get some hardware and get going really quickly, maybe buying a couple of robot arms or something to get our behavior and learning pipelines going while in parallel starting our own robot design. From our experience, after getting a good team together and starting from a clean sheet, a new robot takes about a year to design and build. And then during that period we’ll be securing a customer or two or three.

Radford: We’re also working hard on some very high profile partnerships that could influence our early thinking dramatically. Like Jerry said earlier, it’s a massive 100,000 piece puzzle, and we’re working on the fundamentals: the people, the cash, and the customers.

Reference: https://ift.tt/qUwaVBA

Although a working prototype of the Cyberdesk was never built, the yellow eyepiece suggested a retinal display.Lisa Krohn and Christopher Myers

Although a working prototype of the Cyberdesk was never built, the yellow eyepiece suggested a retinal display.Lisa Krohn and Christopher Myers A port on the back of the Cyberdesk was intended as a neural link.Lisa Krohn and Christopher Myers

A port on the back of the Cyberdesk was intended as a neural link.Lisa Krohn and Christopher Myers Lisa Krohn also designed a flexible wrist computer that could be folded up when not in use. Lisa Krohn

Lisa Krohn also designed a flexible wrist computer that could be folded up when not in use. Lisa Krohn Each “page” of the Krohn’s phonebook represents a separate function—dial phone, answering machine, and printer. Lisa Krohn, Sigmar Willnauer, and Tony Guido

Each “page” of the Krohn’s phonebook represents a separate function—dial phone, answering machine, and printer. Lisa Krohn, Sigmar Willnauer, and Tony Guido Lisa Krohn designed the Cyberdesk in 1993, at a time when wearable computers existed mainly in science fiction. Dietmar Quistorf

Lisa Krohn designed the Cyberdesk in 1993, at a time when wearable computers existed mainly in science fiction. Dietmar Quistorf In 2023, Krohn reimagined the Cyberdesk. It now incorporates technology that hadn’t been available 30 years earlier, such as sensors to monitor brainwaves, hydration, and stress levels.Duvit Mark Kakunegoda

In 2023, Krohn reimagined the Cyberdesk. It now incorporates technology that hadn’t been available 30 years earlier, such as sensors to monitor brainwaves, hydration, and stress levels.Duvit Mark Kakunegoda

Intel’s use of dipole work-function materials means the gate surrounding each fin in a FinFET is thinner.Intel

Intel’s use of dipole work-function materials means the gate surrounding each fin in a FinFET is thinner.Intel